Leading the industry in

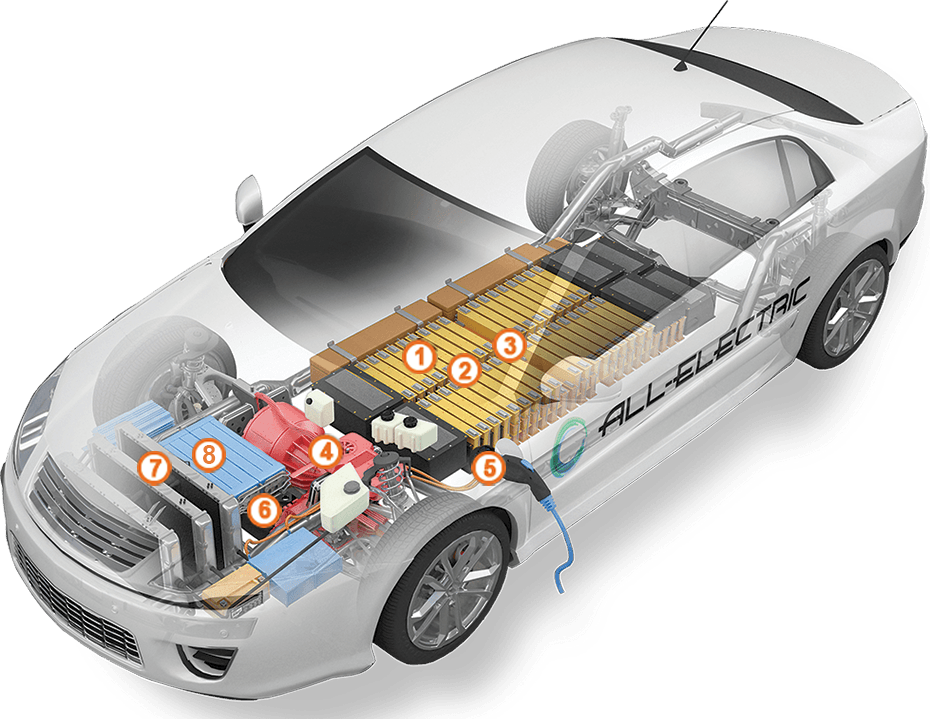

Electrification Solutions for Electric and Hybrid Electric Vehicles (EV/HEV)

Amphenol Sensors is a leading innovator in sensor technologies and measurement solutions. Offering the most diverse sensor portfolio of standard and customized products for the world’s most demanding regulatory and industry-driven applications, Amphenol creates value by providing critical information for real-time decisions.

The advantages of Electric, Hybrid, and Fuel Cell Electric Vehicles have been long-known. To the everyday driver, they offer reduced fuel costs. For the environment, they utilize renewable energy and offer reduced emissions.

Challenges associated with vehicle electrification stem from a limited availability of technologies to enable the use of electricity or hydrogen as a fuel source in a safe and cost-effective manner.

With our vast automotive expertise, engineering resources and manufacturing capabilities, Amphenol Sensors offers various sensor solutions that enable automotive manufacturers to accelerate the electrification of vehicles around the world.